Overview of Lot and Item Mixing Rules

This article will cover how to set up Lot and Item Mixing Rules within Infoplus to gain better control over your warehouse.

To allow for efficient, yet flexible location and inventory management, Infoplus provides Lot and Item Mixing Rules. Mixing Rules control how items are stored in your warehouse. Rule options accommodate a variety of item tracking needs.

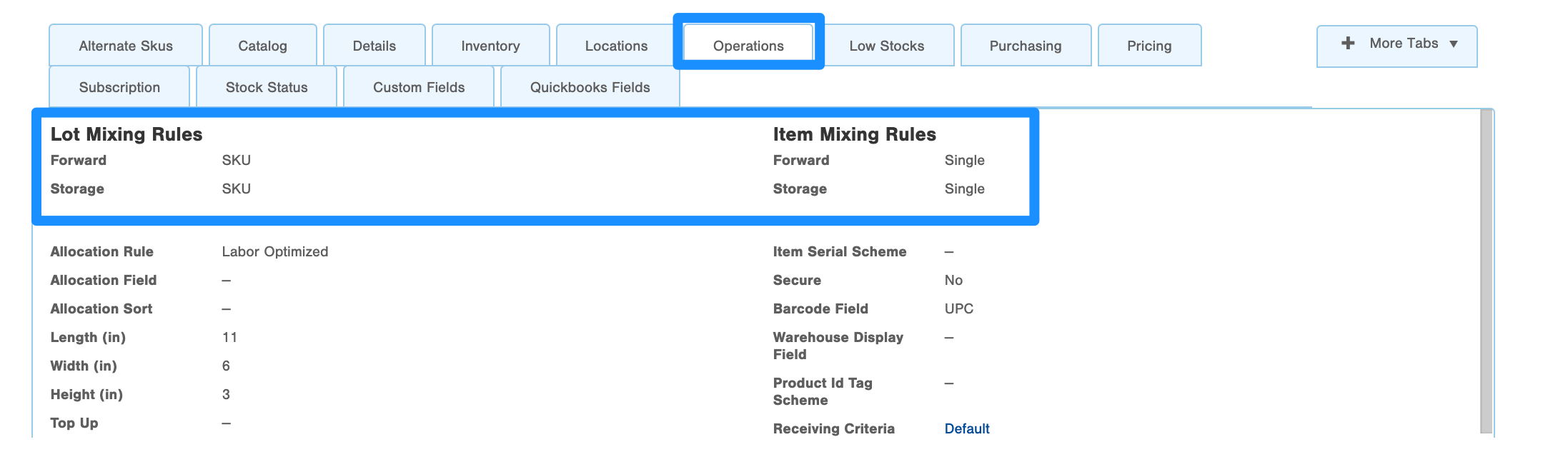

Mixing Rules are set in the Item record. Here's an example:

Lot Mixing Rules

A Lot Mixing Rule uses attributes of an item to control how it can be mixed in a Location (e.g. items in a location all have to have come from the same production lot, items in a location have to have the same SKU but can have different inventory properties).

Lot Mixing Rule options: Item Receipt, Inventory Properties, or SKU.

- Item Receipt: All inventory in a location must have come from the same Item Receipt/Purchase Order (PO) number. This is the most strict Lot Mixing Rule.

- Inventory Properties: All inventory in a location must have the same “attributes” on their POs (e.g. Production Lot, Revision Date, Packaging configuration, etc.); but different PO numbers may be mixed in a location.

- SKU: All inventory in a location must have the same SKU, but any and all variations of PO Numbers and Inventory Properties are allowed to mix. This is the loosest Lot Mixing Rule.

NOTE: Allocation Rules (which control how inventory can be allocated when fulfilling orders) impact which Lot Mixing Rules you should select. For example, if you want to require that items be allocated from the oldest PO lot, you must be storing those items with a Lot Mixing Rule of Item Receipt. See Overview of Allocation Rules for a complete list of allowable Allocation Rule/Lot Mixing Rule combinations.

Item Mixing Rules

An Item Mixing Rule controls if the item is allowed to be mixed with different items (e.g. hot dogs and burgers can reside in the same location).

Item Mixing Rule options: Single or Multi.

- Single: This item must be stored as the only item in a location. It cannot mix with other items.

- Multi: This item can be stored with multiple items, meaning it can mix with other items. NOTE: The Location where you want to allow item mixing must have the "Allow Item Mixing" field set to True.

NOTE: Item Mixing Rules and Lot Mixing Rules are independent of each other. This means that you can mix items (Item Mixing = Multi) and still track information about the item (Lot Mixing = Item Receipt or Inventory Properties). For example, you can still track the production lot of an item even if it's allowed to mix with other items in a location. See the Rules in Action below for a use case.

Forward and Storage Locations

When selecting Mixing Rules, you will select them for an item's Forward Location and its Storage location.

- A Forward Location is a floor-level location that is easy to pick and is reserved for a specific item at any given point of time. Forward Locations are commonly used for Replenishment purposes. A Forward location is a location with a Behavior Type of "Forward Each" or "Forward Case".

- A Storage Location is where the item is stored in the warehouse. A Storage location is any behavior type OTHER than "Forward Each" or "Forward Case".

Rules in Action

Scenario: You want to allow hot dogs and burgers to be stored together in the same location to save space. However, you also want to ensure that no single Location contains two different Production Lots of hot dogs, and that no single location contains two different Production Lots of hamburgers (so that if there is a recall on a given Lot, the items can properly be identified).

Scenario:The Mixing Rule selections to accommodate the above scenario are:

- Lot Mixing Rule for both the Hot Dog and Hamburger items = Inventory Properties (these properties include Production Lot)

- Item Mixing Rule for both the Hot Dog and Hamburger items = Multi

Considerations

Item Mixing may be useful to save space in your warehouse, but before mixing, consider how distinguishable the items are from one another. Similar items stored together may require workers to spend more time trying to identify SKUs within a Location, and there may be greater risk for quality issues, such as mis-picks.

You may want to keep items separate when:

- Items are particularly valuable or otherwise special

- Items are easily confused with other items

NOTE: When mixing items, you may want to consider using the Barcode Field in the Item record, along with a Pick Scan Scheme requiring the item be scanned when picking. In the Barcode Field, select what the Item's barcode represents: SKU, UPC, or Vendor SKU. Requiring the item's barcode be scanned when picking helps ensure the correct product is picked. See Create a Pick Scan Scheme for more information.

Consider restrictions on combinations of mixing rules.

Infoplus will provide feedback regarding improper combinations of rules when saving an Item record. For a complete table of allowable Mixing and Allocation Rules, see Overview of Allocation Rules.