What is a Warehouse Management System?

Your warehouse faces constant pressure: fluctuating order volumes, tight delivery windows, and razor-thin margins. Whether you're managing a 3PL, running an e-commerce fulfillment center, or overseeing manufacturing logistics, a warehouse management system (WMS) provides the control and visibility needed to meet these challenges profitably.

A WMS helps control daily warehouse operations, from receiving goods to inventory control and shipping. The right WMS provides real-time visibility into every process alongside deep integration with other systems, including logistics and business processes, ensuring efficient management throughout the supply chain.

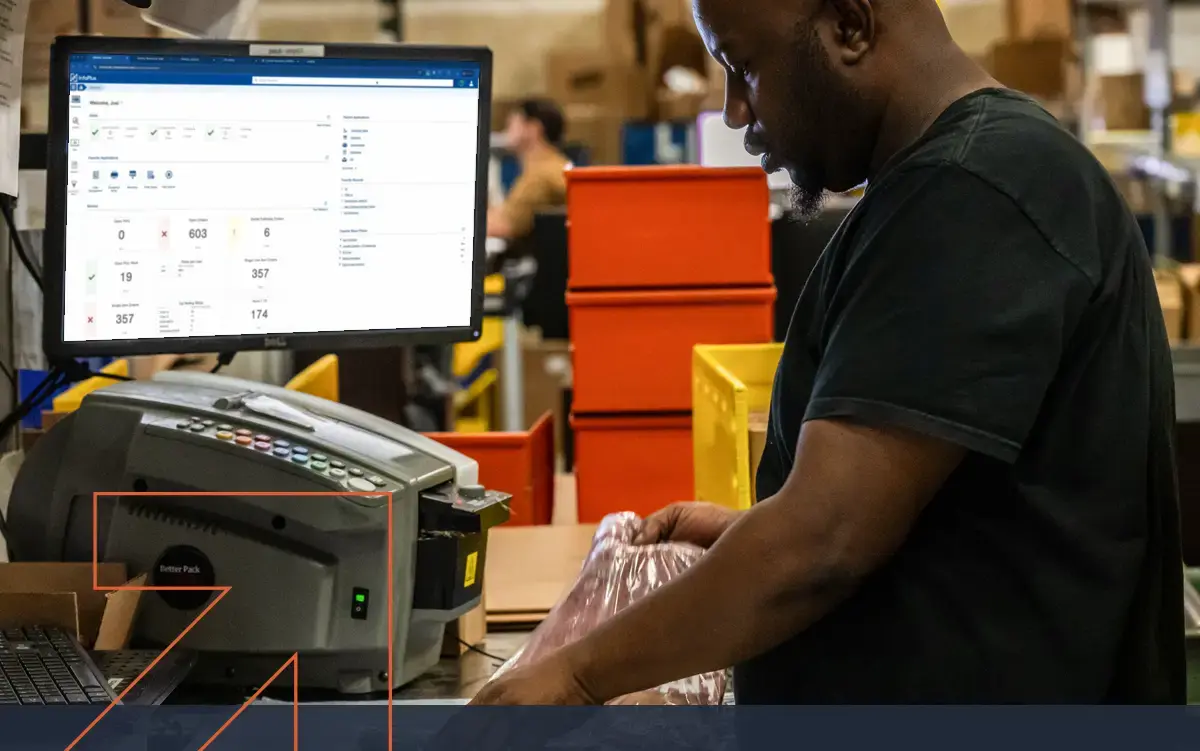

With InfoPlus WMS, businesses gain that visibility into every process—from receiving to shipping—while seamlessly integrating with logistics and business systems to keep the entire supply chain efficient.

Understanding the Warehouse Management System

A warehouse management system is software that orchestrates your entire fulfillment workflow—from receiving through shipping. Modern platforms go beyond basic inventory tracking to coordinate picking routes, automate replenishment, and optimize labor allocation across your facility.

What distinguishes today's platforms is their connectivity. Leading solutions sync with ERP systems, e-commerce platforms, and transportation management tools, eliminating data silos and enabling decisions based on current, accurate information across your supply chain.

Types of Warehouse Management Systems

Warehouse management systems come in several forms, each tailored to different operational needs and business environments. The three primary types are standalone WMS, cloud-based WMS, and integrated WMS solutions that work in tandem with enterprise resource planning (ERP) or supply chain management (SCM) systems.

Any WMS will help you streamline workflows and eliminate tedious, manual processes throughout your warehouse. But the right structure for your business may depend on your specific needs.

A standalone WMS is designed specifically for warehouse management, offering deep functionality for controlling daily warehouse operations, inventory management, and warehouse optimization. While these systems excel at managing warehouse processes, they often require complex integration with other business management systems to achieve a seamless flow of information across the supply chain.

A cloud-based WMS delivers scalability, flexibility and automatic updates. These systems are ideal for businesses experiencing fluctuating demand or those seeking to implement a management system quickly without significant upfront investment. Cloud-based WMS platforms also support efficient warehouse management by enabling remote access and real-time visibility into warehouse operations.

An integrated WMS solution connects directly with ERP or supply chain management systems, providing a unified view of logistics processes and the entire supply chain. This integration allows for end-to-end transparency, improved coordination, and more efficient management of both warehouse and broader business operations. By choosing the right type of warehouse management system WMS, businesses can align their technology with their operational goals and drive greater efficiency throughout their supply chain.

The Core WMS Components That Drive Results

Inventory Management and Control

Modern inventory tracking eliminates the guesswork in warehouse operations. Your WMS shows stock levels, exact locations, and movement patterns updated with each scan—helping you avoid both excess inventory (which ties up capital) and stockouts (which trigger rush orders and frustrate customers). Automated data capture and barcode scanning ensure your system reflects what's actually on your shelves, not what should be there according to last month's records.

Advanced Order Management

Modern order management capabilities within a WMS automatically prioritize orders based on your business rules, optimize picking routes, and coordinate with carrier systems for seamless fulfillment.

While a traditional WMS handles the physical movement and storage of goods, modern systems are incorporating capabilities from order management systems (OMS) as well. These systems often incorporate machine learning and AI across order processing, customer communication and sales channel coordination.

The benefit of the integration? You'll be on track to reduce manual errors that could be costing you thousands in returns and reshipments. And you'll position yourself for omnichannel order management, so you can manage inventory and orders from a single, integrated dashboard.

Labor Management and Optimization

Labor typically represents 50-70% of warehouse operating costs. A WMS reduces these expenses by directing pickers along optimal routes (cutting travel time by up to 30%), tracking task completion rates per worker, and flagging process bottlenecks before they create overtime needs.

The system eliminates time-wasting activities: searching for inventory locations, handwriting pick tickets, or walking back and forth across the facility. Workers receive clear, prioritized task lists on mobile devices, while managers see exactly where productivity lags occur and can address them before they impact delivery schedules.

Reporting and Analytics

Data-driven decision making separates industry leaders from followers. Warehouse management systems provide customizable dashboards, exception reporting, and trend analysis that help you identify opportunities for improvement and demonstrate value to your leadership team and business partners.

The Business Impact: Why WMS Matters for Your Bottom Line

For Third-Party Logistics Operations

Third-party logistics providers juggle inventory for multiple clients, each with unique requirements, while maintaining profitability. A WMS built for 3PLs enables client-specific billing rules, customized reporting dashboards, and inventory segregation—all within a single platform. This multi-tenant architecture lets you scale to handle more clients and higher volumes without adding warehouse staff proportionally. Automated reporting shows each client exactly what they're paying for, building trust while protecting your margins.

For E-commerce Businesses

E-commerce companies dealing with high order volumes and demanding customer expectations need the precision that only a WMS can provide. WMS streamlines fulfillment operations by integrating order processing, inventory management, and delivery logistics, ensuring businesses can efficiently meet modern customer expectations. With features like wave planning and cartonization, these systems ensure orders are fulfilled quickly and accurately, reducing the costly returns that can devastate e-commerce profitability.

For Manufacturers

Manufacturing companies often struggle with complex inventory management requirements, including raw materials, works-in-progress and finished goods. A comprehensive WMS provides the visibility and control needed to optimize inventory levels while supporting lean manufacturing principles. In this context, a distribution center plays a key role in managing inventory and enabling efficient order fulfillment for manufacturers. Understanding industry-specific WMS requirements is crucial for manufacturers looking to streamline their operations.

Key Features That Separate Leading WMS Solutions

Integration Capabilities

Your warehouse management system should seamlessly connect with your existing technology stack. Look for solutions that offer pre-built integrations with popular ERP systems, e-commerce platforms, and shipping carriers. This connectivity eliminates data silos and ensures information flows smoothly across your operation. If you're wondering about WMS vs. ERP systems, the key is understanding that these systems complement rather than replace each other.

Scalability and Flexibility

Growing businesses need systems that can adapt to changing requirements. The best WMS solutions offer flexible configuration options and can scale from single-warehouse operations to multi-site enterprises without requiring complete system overhauls.

Mobile Capabilities

Modern warehouse workers expect mobile-friendly systems that provide real-time information and allow them to update system data from anywhere in the facility. Mobile scanning, picking applications, and dashboard access are no longer nice-to-have features. They're operational necessities.

Advanced Analytics

Beyond basic reporting, leading warehouse management systems leverage machine learning and AI to provide predictive insights about labor requirements, optimal warehouse layouts, and inventory planning. These advanced analytics capabilities help forward-thinking companies stay ahead of operational challenges.

Transportation and Logistics: Streamlining the Supply Chain

Efficient transportation and logistics are essential for a streamlined supply chain, and warehouse management systems play a pivotal role in this process. By integrating with transportation management systems (TMS), advanced WMS platforms enable businesses to optimize shipping routes, select the best carriers, and manage freight more effectively. This seamless integration ensures that inventory control and transportation management work hand-in-hand, reducing delays and minimizing costs.

Warehouse management systems provide real-time visibility into inventory levels and order status, empowering businesses to make informed decisions about logistics processes. Automation of routine tasks, such as shipment scheduling and carrier communication, frees up valuable resources and reduces the risk of manual errors. With the help of machine learning and barcode scanning systems, WMS platforms can predict demand fluctuations, optimize inventory placement, and enhance overall operational efficiency.

Advanced analytics offered by modern WMS platforms further support transportation management by identifying trends, forecasting needs, and uncovering opportunities for continuous improvement. The result is a more agile, responsive supply chain that delivers improved customer satisfaction and supports business growth.

Customer Service: Enhancing the End-User Experience

Customer satisfaction is at the heart of successful warehouse management, and modern warehouse management systems are designed to elevate the end-user experience. By providing real-time visibility into inventory and order status, WMS platforms enable businesses to keep customers informed with accurate, up-to-date information throughout the fulfillment process.

Advanced WMS platforms streamline fulfillment processes with automated workflows, reducing the risk of errors and ensuring that orders are picked, packed, and shipped quickly and accurately. This efficiency not only speeds up delivery times but also minimizes costly mistakes that can erode customer trust.

In today’s dynamic market, changing customer buying patterns require businesses to be agile and responsive. Warehouse management systems help companies adapt by offering flexible fulfillment capabilities and the ability to quickly adjust to shifts in demand. By leveraging the power of WMS platforms, businesses can deliver a superior customer experience, foster loyalty, and maintain a competitive edge in the marketplace.

Compliance and Security in Modern Warehousing

Maintaining regulatory compliance and ensuring security are critical components of modern warehouse management. Warehouse management systems provide the tools and controls necessary to safeguard inventory, monitor warehouse operations, and meet stringent regulatory requirements.

Advanced WMS platforms offer automated tracking and comprehensive reporting features, making it easier for businesses to demonstrate compliance with industry regulations and standards. These systems also support secure access protocols, data encryption, and robust backup and recovery processes, protecting sensitive information and reducing the risk of data breaches.

By implementing a WMS, businesses can create a secure, controlled environment that not only supports efficient warehouse operations but also ensures regulatory compliance. This proactive approach helps mitigate the risk of fines, penalties, and reputational damage, allowing companies to focus on growth and continuous improvement within their supply chain.

The ROI Reality: Quantifying WMS Benefits

Investing in a warehouse management system typically delivers measurable returns within the first year of implementation. Companies commonly see:

- 20-30% reduction in labor costs through automated workflows and optimized picking routes

- 99%+ order accuracy rates that minimize costly returns and reshipments

- 15-25% increase in productivity as workers spend less time searching for inventory and more time fulfilling orders

- Optimized warehouse space utilization, resulting in cost savings and improved storage efficiency

- Improved customer satisfaction scores driven by faster, more accurate order fulfillment

These improvements translate directly to your bottom line while positioning your operation for sustainable growth. For a detailed breakdown of investment considerations, explore our guide on warehouse management system costs.

Implementation Considerations for Success

Choosing the Right Solution

Not all warehouse management systems are created equal. Evaluate potential solutions based on your specific industry requirements, integration needs, and growth plans. Consider factors like implementation timeline, total cost of ownership, and the vendor's track record with companies similar to yours. Our comprehensive warehouse solutions guide can help you understand what features matter most for your operation.

Change Management

Successful WMS implementations require more than software installation. You need to take a strategic approach, incorporating change management strategies that incorporate employee training, process documentation and clear communication about how the new system will benefit both the organization and individual workers. InfoPlus's professional services team specializes in helping companies navigate this transition smoothly.

Data Migration and System Integration

Clean, accurate data is the foundation of WMS success. Invest time in data cleansing and validation before migration, and ensure your integration strategy addresses all critical system connections from day one.

Looking Ahead: The Future of Warehouse Management

The warehouse management system landscape continues to evolve rapidly. Emerging technologies like artificial intelligence, machine learning, and robotic process automation are being integrated into leading WMS platforms, providing even greater opportunities for optimization and cost reduction. Supply chain leaders are leveraging these AI transformation investments to achieve significant ROI and improve overall supply chain operations.

Companies that invest in modern, scalable warehouse management systems position themselves to take advantage of these technological advances while building the operational foundation needed for sustained growth.

Take Control of Your Warehouse Operations

For mid-market companies ready to thrive in today's complex supply chain environment, WMS implementation isn't an option, it's an imperative.

The most successful warehouse operations combine powerful technology with strategic implementation and ongoing optimization. By choosing a WMS that offers the flexibility to adapt to your changing requirements and the scalability to grow with your business, you're doing more than solving today's operational challenges, you're building the foundation for tomorrow's success.

Ready to discover how a modern warehouse management system can transform your operations? The right WMS does more than manage your warehouse. It drives profitability, improves customer satisfaction, and positions your business for sustainable growth in an increasingly competitive marketplace.

Contact our warehouse experts to learn how InfoPlus can help you take control of your warehouse operations and achieve the results your business deserves.

.png?width=225&height=60&name=Logo%20(7).png)